Q1.After firing, the material seems to turn yellow. Why?

Possible reasons for this are as follows:

Q2.Does using a metallic spatula to mix porcelain have any effect on color after firing?

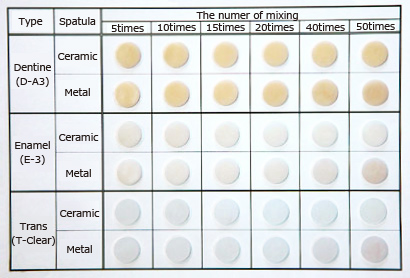

When mixing porcelain powder with a metallic spatula on the glass board, metallic powder gets mixed in the porcelain powder; this affects the color after firing.

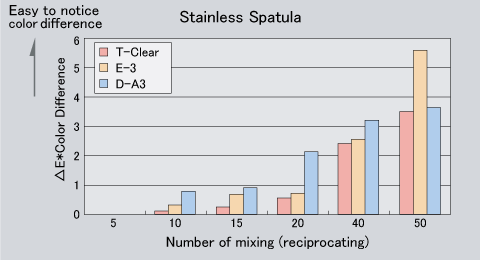

Chart 2 indicates the color differences, depending on the amount of blending time using a metallic spatula. The longer the blending time, the bigger the color difference is.

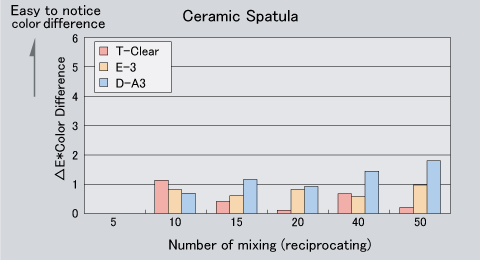

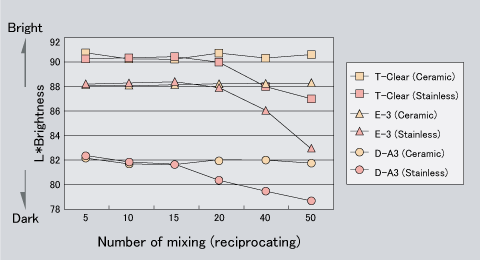

On the other hand, the chart 3 indicates that blending with a ceramic spatula doesn’t influence on color. Also, Chart 4 indicates that the longer blending is performed with a metal spatula, the darker the material becomes.

Chart1:Test of Color Difference of Fired Wet pellets

Chart2:Color Difference when Stainless Spatula is used to mix ZEO CE LIGHT

Chart3:Color Difference when Ceramic Spatula is used to mix ZEO CE LIGHT

Chart4:Difference of Brightness

Q2-2.Does your company offer a ceramic spatula for ZEO CE LIGHT?

Yes, we offer the “ZEO CE LIGHT ceramic spatula” in the “ZEO CE LIGHT Total Solutions Series” for technicians requiring high-precision porcelain. ZEO CE LIGHT Ceramic Spatula is made of toughened zirconia and it has no influence on colors whatsoever. It can be used not only with ZEO CE LIGHT, but also all porcelain powders.

ZEO CE LIGHT Ceramic Spatula

Q2-3.What is toughened- zirconia, used for the spatula blade?

Zirconia (ZrO2) is oxidized zirconium; the quality of material is classified as a ceramic. The material is also used in the ceramic powder as emulsifier. Controlling Zirconia’s crystal architecture by a special method, (stress-induced transformation) modifies it into metastable tetragonal zirconia and makes the ceramic dramatically tougher*. By this technology, the ceramic is enabled to overcome weak point such as fragility. Also, the extremely small crystal particles make the surface unstriated and excellent at abrasion resistance. Today, zirconia is used for adiabatic materials, scissors, knives, engine components and bearings

*Toughness…Applying external force provokes plastic deformation and it requires huge amounts of energy for the material to be destroyed.

Q2-4.What are the features of ZEO CE LIGHT Ceramic Spatula?

Q2-5.Are there any cautions regarding use of the spatula?

Q3.Stain can be used for both internal layers and the outer surface, but why is the firing temperature different?

Stain can be used for both internal layers and the outer surface. However, if stain for internal layers fired at the same temperature as for the outer surface, internal stain will be glazed and will repel the powder at the secondary bake.

We set the temperature for internal stain so as to get the color to come out adequately. When fired at 820℃, it will be slightly opaque, but repeat firing it will cause it to become more transparent. Therefore, the temperature does not need to be high, even for the incisal edge.

Q3-2.Why does the internal stain need to be vacuum fired and external stain need to be atmosphere fired?

In the VD series, there are 4 shades, A1-A4, which can be used alone. The product instructions are the same as for normal Dentine. The firing temperature and schedule are also same. VSP is the color-adjusting powder. Please blend VSP with normal Dentine. Depending on the shade, the ratio can vary from 3:1 to 1:1. ( See Table 1 below)

Q3-3.Is it possible to mix Stain and Dentine powder?

If you mix Stain and Dentine powder, please use Stain Powder. Stain Paste contains stain liquid. Stain liquid contains more organic ingredients than modeling liquid and it influences coloring. Also, the viscosity will be higher and the handling will be poor. For these reasons we recommend using Stain Powder.

Q4.How can I express Noritake’s Cervical CV-1 to CV-4?

By mixing MARGIN 2004 and Accent, we can make colors, similar to NORITAKE’s cervical color.

MARGIN 2004/ M-5・M-3 Accent/ T-Amber・Occlusal-Orange・Occlusal-Brown

| ZEO CE LIGHT | |||

| NORITAKE Cervical |

MARGIN 2004 |

Accent | |

| CV-1 | M-5;1 | T-Amber;2 | - |

| CV-2 | M-3;1 | T-Amber;2 | Occlusal-Orange;1 |

| CV-3 | M-3;1 | Occlusal-Brown;0.25 | Occlusal-Orange;0.5 |

| CV-4 | M-3;1 | T-Amber;2 | Occlusal-Orange;1 |

The color differences are not measured. Please refer to the mix ratio as a rough standard.

YAMAKIN will respond to inquiries on the business day.

If we receive any inquiries during company holidays such as

Saturdays, Sundays, public holidays in Japan,

we will reply to you on the next day.

Business Hours: Weekday 8:45am to 17:45pm.