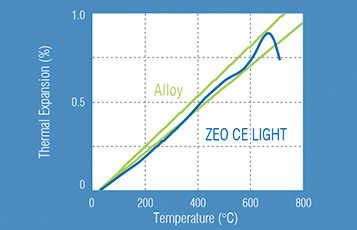

The features of ZEO CE LIGHT are shown below. It is outstanding in many aspects in reproducing almost identical characteristics as natural teeth. Ideal firing temperature, stable thermal expansion and strong adhesion to any metals prevent cracks. Optical properties such as fluorescence, transparency, opalescence and light transmission provide a similar or same appearance as natural teeth.

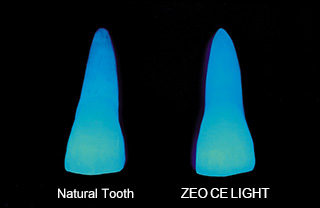

Natural Tooth Fluorescence and ZEO CE LIGHT |

Natural teeth emit a peculiar fluorescence under ultraviolet rays. Moreover, a natural tooth is composed of enamel, dentine and dental pulp, each of which exhibits different fluorescence. ZEO CE LIGHT succeeds in faithfully reproducing the fluorescence of natural teeth.

Opalescence of Natural Teeth and ZEO CE LIGHT |

Natural teeth have the characteristic of looking pale in reflected light and orange in transmitted light, and both combined appear as the natural color of teeth. This effect is called opalescence, and very important in reproducing natural teeth.

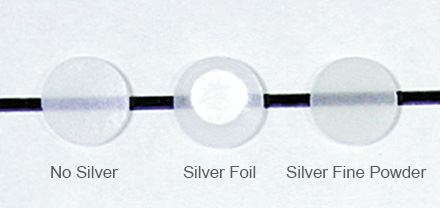

Discoloration test of ZEO CE LIGHT Translucent porcelain against silver |

At present, harmful chemical elements are used in many kinds of porcelain in order to suppress yellowish discoloration by silver. Using new technology, ZEO CE LIGHT succeeds in effectively suppressing yellowish discoloration without using harmful chemical elements. ZEO CE LIGHT is superior in safety, having been developed with consideration given to bioaffinity and the environment.

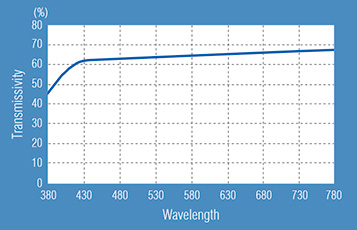

Curve of Transmissivity of Translucent Porcelain |

In order to reproduce the color of natural teeth, colorless and transparent porcelain - the color of which is easy to adjust with pigments and emulsifiers – is required. ZEO CE LIGHT is produced with colorless and transparent porcelain as its base. Furthermore, ZEO CE LIGHT uses a special porcelain, “Accent”, to reproduce the subtle color tones of natural teeth.

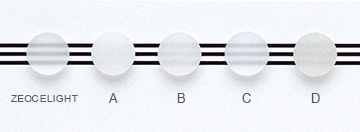

Transparency of Translucent Porcelain

Transparency of Translucent Porcelain

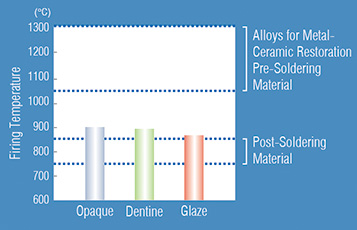

Firing Temperature of Porcelain Operating Temperature of Alloys, Pre-Soldering and Post-Soldering Material Firing Temperature |

The firing temperature of ZEO CE LIGHT is between 880°C and 920°C. This presents no danger of metal frames or pre-soldering materials changing their shape, and prevents surface properties being subject to the detrimental influence of soldering after firing the porcelain. That is, its firing temperature is ideal for porcelain fused to metal.

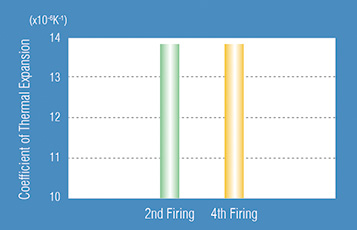

Fluctuation of Thermal Expansion by Repeated Firing |

ZEO CE LIGHT is an epoch-making porcelain, suitable for a wide range of metals. Cracks caused by the mismatch of thermal expansion coefficient have often arisen in the existing metal-ceramic systems. Because ZEO CE LIGHT stabilizes leucite crystals in an original way, its thermal expansion coefficient is so stable that it prevents cracks even if it is fired repeatedly.

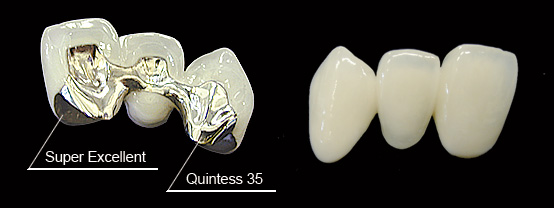

Crack test result of metal ceramic restoration combining different types of alloys |

For metal ceramic restoration products, problems such as cracks after firing or fractures in the mouth must be avoided. ZEO CE LIGHT exhibits stable anti-crack behavior, even in cases where alloys with different thermal expansion rates (13.7 vs. 14.6) are combined.

Thermal Expansion between ZEO CE LIGHT and Alloy |

Using our own special technique, our opaque material comes in two kinds, so as to remarkably improve adhesive strength. Super Opaque is superior in adhesion, while Shade Opaque has the same color as Dentine. This solves the problems of cracks and exfoliation after being fitted in the mouth and realizes strong adhesion for metal-ceramics.

YAMAKIN will respond to inquiries on the business day.

If we receive any inquiries during company holidays such as

Saturdays, Sundays, public holidays in Japan,

we will reply to you on the next day.

Business Hours: Weekday 8:45am to 17:45pm.