Q1.How to use Super Opaque and Shade Opaque?

| A-1 | Stir paste opaque in the container with a ceramic spatula evenly (please do not use metallic one). Paste opaque in the container has been somewhat hardened. This is because hard paste can be softened, but it is impossible to harden soft paste. |

| A-2 | Take out an appropriate amount of opaque on a mixing plate. As there may be bubbles in the opaque, rub the paste with a ceramic spatula. |

| A-3 | If the paste is hard for application, please add a small amount of Opaque Liquid on the mixing slab. For conditioning paste, use the tip of a spatula and add Opaque Liquid little by little. Do not add Opaque Liquid directly, as it may cause the paste to be extremely soft. |

| A-4 | Describe a few circles with a glass rod to see if they gradually disappear. If they do, paste condition is suitable for application. If paste is too hard, their traces clearly remain, and if soft, most of them disappear. |

| A-5 | Use a glass rod to apply thinly and equally and do condensation. Add a small amount of opaque on the margin area shrunk by condensation and corner part where metal color is seen. |

Q2.Bubbles and cracking are found after firing opaque?

There are two primary causes. Drying of liquid in the paste opaque is not adequate or opaque porcelain is not fired enough. Following measures are effective.

Point 1. Extend dry time.

It is necessary to completely dry the liquid in paste opaque before firing opaque porcelain. Required dry time is different depending on the thickness of layers to be applied on. Be sure to dry 5 minutes or more for single crowns, 8 minutes or more for triple bridges, and longer time for long span bridges.

Point 2. Lower start temperature of firing.( 500℃ >>> 450℃ or below)

To lower start temperature of firing is also effective, as a difference between start temperature and the temperature range in which fusing of porcelain particles starts will be large. As a result, fluid can be effectively dried. If start temperature is set high, fluid boils due to rapid heating. This may cause cracking of porcelain.

Point 3. Raise firing temperature. (920℃ >>> 930℃ or over)

If you do not fire porcelain enough, bubbles are also found. If firing is not enough, porcelain particles do not fuse enough. As a result, voids in the space where the liquid evaporated through (bubbles) remain. The strength of porcelain to be fused to an alloy also weakens.

Fine emulsifier has been used for Zeo Ce Light. Therefore, it is possible to emulsify porcelain by adding a small amount of emulsifier without changing its original properties. Furthermore, the color of natural teeth, especially opalescence, can be reproduced uniformly.

Q3.Is bonding strength of Super Opaque affected due to differences in firing temperatures?

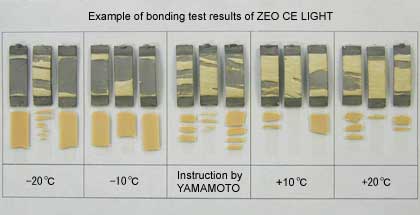

One factor which affects bonding strength is that porcelain particles are not fired enough. Therefore, when firing temperature is lower than the proper temperature range, bonding strength may weaken. We carried out bonding tests at various firing temperatures. Their results have been introduced below.

【 Test method 】

Super Opaque, Shade Opaque, and Dentine porcelain were built up and fired at ±20℃ of firing temperatures instructed by manufacturers (plate metal was used). After firing, both edges of the plate were bent with a plier until porcelain exfoliated. Bonding conditions after exfoliation were visually checked.

| 【 Furnace used 】 | MASTER ACCEL-21 (KDF) |

| 【 Metal used 】 | QUINTESS CERAFY (Au 56%,Pt 2%,Pd 24.5%,Ag 13%) |

| 【 Dimension of plate metal 】 | 25mm × 7mm × 0.5mm |

| 【 Surface treatment of metal 】 | Same as in the manual of QUINTESS CERAFY |

| 【 Amount of build-up 】 | Area of build-up: 15mm × 7mm Thickness: about 1mm |

| 【 Firing schedule 】 | Firing of Super Opaque, Shade Opaque, and Dentine porcelain as well as glaze bake were carried out at ±20℃ of the basic firing schedule in the manual. |

【 Test results 】

| -20℃ | -10℃ | Instruction by YAMAMOTO |

+10℃ | +20℃ | |

| Sample ① | × | △ | ○ | ◎ | ◎ |

| Sample ② | △ | ○ | ◎ | ◎ | ◎ |

| Sample ③ | × | △ | ◎ | ◎ | ◎ |

* Evaluation of bonding conditions

◎ = Super Opaque and Dentine porcelain were attached to almost all parts of the fused area.

○ = Super Opaque was attached to almost all parts of the fused area.

△ = Super Opaque was partially attached.

× = Super Opaque was hardly attached.

The test results show that the bonding condition of Super Opaque is good when firing temperature is set slightly higher than the instructed temperature. However, when temperatures are set low, porcelain is not fused to metal enough. This may cause decline in bonding strength. Although the plate was fairly bent and many cracks were found, Dentine porcelain was attached to almost all parts of the fused area especially on the samples evaluated as ◎.

* Super Opaque has been developed to achieve excellent adhesion regardless of types of metal. However, bonding conditions may slightly differ depending on types of metal or methods of surface treatment.

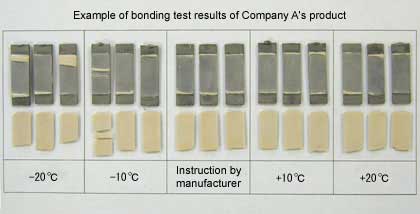

Q4.Are Opaque products of other companies also affected by differences in firing temperatures?

It depends on manufacturers. But generally, firing temperatures are thought to affect bonding strength of porcelain. We conducted bonding tests at various firing temperatures. Their results have been shown below.

【 Test method 】

Primary Opaque, second Opaque, and Dentine porcelain were built up and fired at ±20℃ of firing temperatures instructed by manufacturers (plate metal was used). After firing, both edges of the plate were bent with a plier until porcelain exfoliated. Bonding conditions after exfoliation were visually checked.

| 【 Furnace used 】 | MASTER ACCEL-21 (KDF) |

| 【 Metal used 】 | QUINTESS CERAFY (Au 56%,Pt 2%,Pd 24.5%,Ag 13%) |

| 【 Dimension of plate metal 】 | 25mm × 7mm × 0.5mm |

| 【 Surface treatment of metal 】 | Same as in the manual of QUINTESS CERAFY |

| 【 Amount of build-up of porcelain】 | Area of build-up: 15mm × 7mm Thickness: about 1mm |

| 【 Firing schedule 】 | Firing of primary Opaque, second Opaque, and Dentine porcelain as well as glaze bake were carried out at ±20℃ of the basic firing schedule instructed by each manufacturer. |

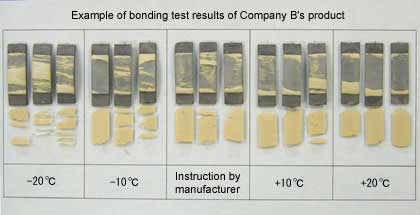

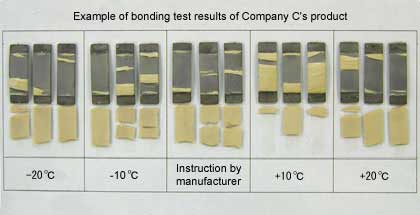

【 Tests results of other companies' products 】

| -20℃ | -10℃ | Instruction by manufacturers | +10℃ | +20℃ | ||

| Company A | Sample ① | △ | × | × | × | × |

| Sample ② | △ | × | × | × | × | |

| Sample ③ | △ | △ | × | × | × | |

| Company B | Sample ① | ◎ | ◎ | ○ | ○ | × |

| Sample ② | ◎ | ◎ | ◎ | △ | × | |

| Sample ③ | ◎ | ○ | ○ | ○ | △ | |

| Company C | Sample ① | △ | △ | ◎ | × | |

| Sample ② | △ | △ | △ | △ | × | |

| Sample ③ | △ | △ | × | ◎ | △ | |

* Evaluation of bonding conditions

◎ = Opaque and Dentine porcelain were attached to almost all parts of the fused area.

○ = Opaque was attached to almost all parts of the fused area.

△ = Opaque was partially attached.

× = Opaque was hardly attached.

【 Company A 】

Opaque was slightly attached to metal only when firing temperature was set lower than the temperature instructed by its manufacturer. Opaque was not attached at all the rest of firing temperatures. Porcelain exfoliated before a plate bent. Changing a method of surface treatment may be effective in increasing bonding strength of porcelain. However, it can result in poor adhesion especially to this metal. The results only apply to specific types of metal, not to all kinds of metal.

【 Company B 】

At the temperature instructed by its manufacturer and low temperatures, Opaque was attached to metal on the whole. However, bonding strength declined and Opaque was not attached to metal at 20℃ higher than the instructed temperature. Although it depends on types of metal or conditions of surface treatment, setting firing temperatures high is not appropriate.

【 Company C 】

Dentine porcelain was attached to metal enough at the temperature 10℃ higher. However, bonding of their porcelain is weak compared to that of Company B.

Furthermore, setting the temperature 20℃ higher can cause weakness and instability of bonding strength.

YAMAKIN will respond to inquiries on the business day.

If we receive any inquiries during company holidays such as

Saturdays, Sundays, public holidays in Japan,

we will reply to you on the next day.

Business Hours: Weekday 8:45am to 17:45pm.