Q1: Are condition of firing difsferent depending on types of porcelain furnace?

Characteristics of porcelain furnaces are different depending on their manufacturers, and conditions of firing are also slightly different. We conducted firing tests for Super Opaque and Shade Opaque of Zeo Ce Light in three types of porcelain furnaces based on a basic firing schedule. Their results have been shown below. In the tests, Programat P100 (IVOCLAR), COMMODORE75 VPF (JELENKO), and MASTER ACCEL-21 (KDF) were used.

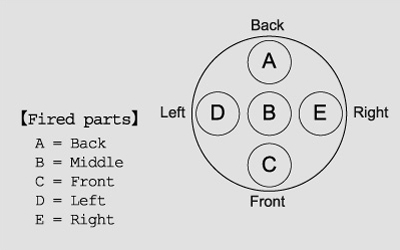

1.Surface conditions of each fired part depending on firing temperature of each porcelain furnace when firing Super Opaque.

| 【 Firing board 】 | Stand a 1cm Nichrome wire on a fire-resistant insulating board of 4cm × 4cm (width) ×1cm (height) |

| 【 Frame 】 | Single crown |

| 【 Porcelain used 】 | Super Opaque |

【 Test Results 】

| Firing Schedule | Programat P100 | COMMODORE 75VPF | MASTER ACCEL 21 | ||||||||||||

| Dry / Start / Firing / Hold | A | B | C | D | E | A | B | C | D | E | A | B | C | D | E |

| 5min/500℃/930℃/1min | ● | ○ | ◎ | ● | ○ | ||||||||||

| 5min/500℃/920℃/1min | ○ | ○ | ● | ● | ● | ○ | ○ | ◎ | ● | ● | ◎ | △ | △ | ◎ | ◎ |

| 5min/500℃/910℃/1min | ○ | ○ | ● | ● | ● | ○ | ○ | ◎ | ○ | ○ | ◎ | △ | △ | ◎ | ◎ |

| 5min/500℃/900℃/1min | ○ | ○ | ● | ● | ● | ○ | ○ | ◎ | ○ | ○ | △ | × | × | △ | △ |

| 5min/500℃/890℃/1min | ◎ | ◎ | ○ | ○ | ○ | ◎ | ◎ | △ | ◎ | ◎ | |||||

| 5min/500℃/880℃/1min | ◎ | ◎ | ◎ | ○ | ○ | × | × | × | △ | △ | |||||

| 5min/500℃/870℃/1min | △ | △ | △ | △ | △ | × | × | × | × | △ | |||||

| 5min/500℃/860℃/1min | × | × | △ | × | × | ||||||||||

* Vacuum rate during firing is 73cmHg, which is set at start temperature of firing and released at firing-temperature. Heating rate is 60℃/min.

| 【 Conditions of firing 】 | ● = Too bright (overfiring) ○ = A little bright ◎ = Appropriate △ = A little dull × = Dull (firing is not enough) |

| 【 Appropriate range 】 | ■ = Inside the color |

【 Results 】

■ Programat P100

An electric wire is wrapped inside the furnace, in 5 lines in the front area and 4 in the back area. Therefore, the front part relatively tends to be overfired. To fire under proper conditions, it is required to set the temperature at 30 to 40℃ below the basic firing schedule.

■ COMMODORE75 VPF

In the front area, there is a space where an electric wire is not wrapped, as there is a peephole. Therefore, the back area and right and left sides tend to be slightly overfired. To fire under appropriate conditions, you should set the temperature at 10 to 30℃ below.

■ MASTER ACCEL-21

As there is a peephole as well as at COMMODORE75 VPF, an electric wire is not wrapped in some parts of the front area. Therefore, the back area and right and left sides tend to be slightly overfired. However, you can fire uniformly if the basic firing schedule is used.

2.Surface conditions of each fired part depending on firing temperature of each porcelain furnace when firing Shade Opaque.

| 【 Firing board 】 | Stand a 1cm Nichrome wire on a fire-resistant insulating board of 4cm×4cm (width)×1cm (height) |

| 【 Frame 】 | Single crown |

| 【 Porcelain used 】 | Super Opaque |

【 Test Results 】

| Firing Schedule | Programat P100 | COMMODORE 75VPF | MASTER ACCEL 21 | ||||||||||||

| Dry / Start / Firing / Hold | A | B | C | D | E | A | B | C | D | E | A | B | C | D | E |

| 5min/500℃/920℃/1min | ◎ | ◎ | △ | ○ | ○ | ||||||||||

| 5min/500℃/910℃/1min | ○ | ○ | ◎ | ○ | ○ | ◎ | △ | × | △ | △ | |||||

| 5min/500℃/900℃/1min | ◎ | ◎ | × | △ | △ | △ | × | × | △ | × | |||||

| 5min/500℃/890℃/1min | △ | △ | × | △ | △ | ||||||||||

| 5min/500℃/880℃/1min | ◎ | ◎ | ○ | ○ | ○ | ||||||||||

| 5min/500℃/870℃/1min | △ | △ | ◎ | △ | △ | ||||||||||

| 5min/500℃/860℃/1min | × | × | △ | × | × | ||||||||||

* Vacuum rate during firing is 73cmHg, which is set at start temperature of firing and released at firing temperature. Heating rate is 60oC/min.

| 【 Conditions of firing 】 | ● = Too bright (overfiring) ○ = A little bright ◎ = Appropriate △ = A little dull ×-= Dull (firing is not enough) |

| 【 Appropriate range 】 | ■ = Inside the color |

In this test, firing conditions were checked after Shade Opaque was applied on Super Opaque properly fired in the Test 1.

【 Results 】

■ Programat P100

Shade Opaque was properly fired at 5 to 10℃ below the firing temperature of Super Opaque. Furthermore, temperature needs to be set at 40 to 45℃ below that of the basic firing schedule.

■ COMMODORE75 VPF

Shade Opaque was properly fired at about 5℃ below the firing temperature of Super Opaque. Furthermore, temperature needs to be set at about 15℃ below that of the basic firing schedule.

■ MASTER ACCEL-21

Relatively, Shade Opaque is uniformly fired based on the basic firing schedule.

* Temperatures of each porcelain furnace may be slightly different due to various factors such as differences in conditions of a muffle and time of replacement.

The above results do not necessarily apply to all porcelain furnaces of the same type and those being sold abroad. In the tests, furnaces sold in Japan were used. Please use the results for reference.

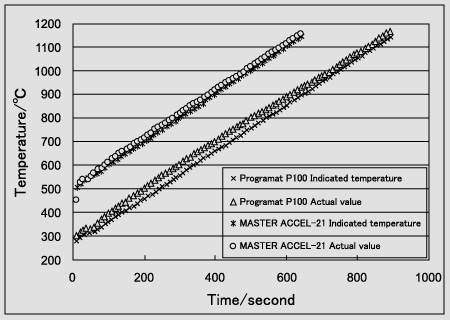

Q2: Is there a difference between the indicated temperature and the inside temperature of a porcelain furnace?

It appears that they are slightly different. Actual values of inside temperatures and indicated temperatures of Programat P100 (IVOCLAR) and MASTER ACCEL-21 (KDF) have been stated below for reference.

【 Method of measurement 】

The tip of thermocouple was set at the middle of the inside, about 2cm height (height of the metal frame on the firing board). Differences between indicated temperatures and actual temperatures were checked from at 500℃ of start temperature to 1,150℃ every 10 seconds.

【 Schedule to raise temperature 】

Start temperature was set at 500℃, and maximum temperature was 1,150℃. Heating rate was 60℃/min.

* Measurement of Programat P100 was started at 300℃, as this product was designed to be sealed at 300℃.

■ Programat P100

There was a difference of about 40℃ between the indicated temperature and actual value. Differences were larger in the low-temperature range. This is because the position of the thermocouple in the furnace was so close to the heater part and thus temperatures differed from those of the middle part.

■ MASTER ACCEL-21

There was 15℃ of difference, but it is practically fixed. As the position of the thermocouple of the furnace is slightly apart from the heater part, temperature differences are small. This 15oC difference was conceivably caused by the protect tube of the thermocouple. Therefore, there is virtually no temperature difference.

* Temperatures of each porcelain furnace may be slightly different due to various factors such as differences in conditions of a muffle and time of replacement.

The above results do not necessarily apply to all porcelain furnaces of the same type and those being sold abroad. In the tests, furnaces sold in Japan were used. Please use the results for reference.

YAMAKIN will respond to inquiries on the business day.

If we receive any inquiries during company holidays such as

Saturdays, Sundays, public holidays in Japan,

we will reply to you on the next day.

Business Hours: Weekday 8:45am to 17:45pm.

News

Photo Gallery